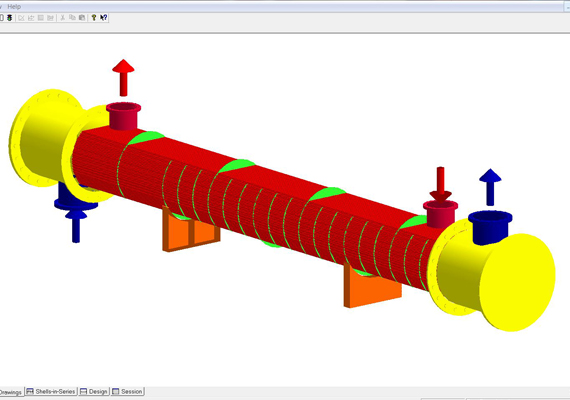

HTRI TRAINING COURSE

This course is suitable to a wide range of Technical Professionals but will greatly benefit:

- Engineers in disciplines Process, Mechanical, Project acting as specialist or generalist.

- Design Specialist in heat exchanger to extend their knowledge HTRI specific

- Engineers in various disciplines; Maintenance, Turn-Around, & Cost Estimating

By the end of this course, participants will be able to perform or become:

- Proper Heat Exchanger Selection

- Heat Exchanger sizing

- Active Communicator during Meetings with Vendors

- Better observer during final inspection of heat exchangers

- Clear understanding of HTRI results

Course Outline

Day One: Shell & Tubular

- Historical & Market Aspects

- Basic Heat Transfer

- Mean Temperature Difference & Thermal Efficiency

- Fundamentals of Stream Analysis

- TEMA Nomenclature & Selection

- Shell, Bundle, Baffle and Tube type Selection

Day Two: Shell & Tubulars Advanced Technologies

- Fouling

- Tube Insert Technologies

- Low-fin, High-flux, Corrugated and Twisted Tube applications and examples

Day Three: Vibration Analysis and HTRI / TEMA Case Studies

- Tube Vibration and FIV Prevention Technologies

- Case Study Selection of TEMA type

- HTRI Case study

Day Four: HTRI Thermal Design Aspects Condensers & Reboilers

- Practical Aspects of Condenser Design (Reflux, Vent, Shellside versus Tubeside)

- Practical Aspects of Reboiler Design (Thermosyphon, Kettle, Falling Film)

You may send us queries to get quote for this training course individually @ info@chemted.com